He aha tefehokotaki'anga pewa-waa?

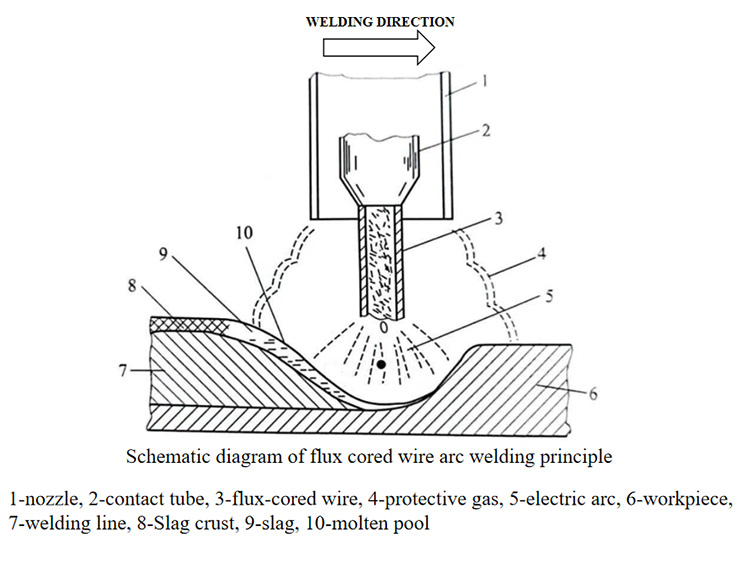

Ko te pewa waea a Flux-cored he tikanga weriweri e whakamahi ana i te pewa i waenga i te waea rewharewha me te taputapu mahi hei whakamahana, a ko tana ingoa Ingarihi he FCAW noa.I raro i te mahi o te wera arc, ka honoa te whakarewa waea me te taputapu mahi ma te whakarewa, ka hanga he poka wai, ka anga whakamua i muri i te whakamaaramatanga o te hiku poka wai.

He aha te waea rewharewha?He aha nga ahuatanga o te kariri?

Ko te waea whakapiringa-a-Waea he momo waea whakapiri i hangaia ma te huri i te riipene rino angiangi ki roto i te paipa maitai, te putorino maitai motuhake ranei, ka whakakiia te paipa ki etahi waahanga o te paura, me te tuhi.Ko te hanganga o te paura paura he rite ki tera o te paninga electrode, ko te nuinga o te tito o te arc stabilizing agent, slag forming agent, gas forming agent, alloying agent, deoxidizing agent, etc.

He aha te mahi o te rere i roto i te waea rewharewha?

Ko te mahi o te rere he rite ki tera o te paninga hiko, a ko te nuinga o nga momo e whai ake nei.

① Te parenga o etahi o nga waahanga i roto i te pakaru o te rewharewha, te whakarewatanga o etahi!Ko te pirau o te rere fehokotaki'anga ka tuku hau, he whakamarumaru etahi, te nuinga ranei.Ko te rewharewha rewa ka hanga he para rewa, e kapi ana i te mata o te topata me te puna rewa, ka tiakina e te whakarewa wai.

② Ka taea e te kariri arc stabilizer te whakau i te pewa me te whakaheke i te reiti mokowhiti.

③ Te mahi whakakotahi Ko etahi o nga huānga koranu i roto i te matua ka taea te whakakotahi i te paihere.

④ Ko nga huānga koranu whakahaoratanga o te para ka tauhohe ki nga konganuku wai.Whakapai ake i te hanganga o te whakarewa whakarewa, te whakapai ake i ona ahuatanga miihini.

I tua atu, ka taea hoki e te parae hipoki te whakaiti i te reiti whakamahana o te puna rewa, te whakaroa i te waa o te puna rewa, he pai ki te whakaiti i te ihirangi o te hau kino i roto i te weld me te aukati i te porosity.

He aha te ahua o te pewa whao rere kee?

E rua nga momo o te rewharewha waea arc fehokotaki'anga (FCAW-G) me te tiaki-whaiaro fehokotaki'anga (FCAW-S), i runga i te whakamahi i te hau parepare waho ranei karekau.

I te nuinga o te wa ka whakamahia te waro maru o te waea rewharewha, te waro hauhaa me te argon hei hau whakamarumaru, a, he iti noa te kaikawe hau i te rere o te waea.Ko tenei tikanga he rite ki te hau whaanui maru maru.Karekau e hiahiatia he hau whakamarumaru o waho ki te whakapiringa tiaki-whaiaro.He nui te tini o te hau i roto i te rere, a ka whakamahia te hau me te para i whakangoatia e te kaahini hei whakamarumaru.

He aha nga painga o te whakahiato pewa-kore?

Ko nga painga e whai ake nei ko te whakapiri arc-cored arc.

(1) Ko te hua o te welding teitei te pai o te whakarewatanga (tae atu ki te 85% ~ 90%), te tere tere rewa;Mo te whakapiri papatahi, ko te tere o te paninga he 1.5 nga wa o te peera a-ringa, a mo etahi atu tuunga raima, ko te 3-5 nga wa o te peera a-ringa.

② He iti te pakaru, he pai te hanga i te matua raau taero kua tapirihia te whakapumau arc, na reira ka mau te pewa, te paku iti, te pai o te hanga.Na te mea kua hipokina te puna rewa ki te para rewa, he pai ake te ahua o te mata o te mata i tera o te waro hauhā.

(3) He pai te kounga o te whakahiato Na te mea he parepare te whakakotahitanga o te hau para, ka kaha ake te aukati i te hau kino mai i te uru ki te rohe whakapiri.I tua atu, he roa te wa o te puna rewa, he pai ki te rerenga hau, no reira he iti te hauwai me te pai o te porosity o te weld.

(4) Ko te kaha urutau anake me whakatika i te hanganga o te waea solder cored, ka taea e ia te whakatutuki i nga whakaritenga o nga tira rereke i runga i te hanganga weld.

He aha nga huakore o te whakahiato pewa-waa?

Ko nga ngoikoretanga o te whakapiringa arc-cored arc e whai ake nei.

Ki te whakatauritea ki te whakaahuru maru hau, he nui ake te utu mo te waea whakapiri, he uaua te mahi hangahanga.

② He uaua te whangai waea, me whakamahi te miihini whangai waea ka taea te whakatika tika te pehanga awhi.

③ He ngawari te kariri ki te tango i te makuku, no reira me mau tonu te waea whakapiri.

④ Ka hiahiatia te tango para i muri i te whakapiri.

⑤ He nui ake te auahi me nga hau kino ka puta mai i roto i te mahi whakapiri, no reira me whakakaha te hau.

He aha te hau whakamarumaru i te nuinga o te wa e whakamahia ana i roto i te whaowhanga pewa-waa?He aha nga ahuatanga o ia tangata?

I te nuinga o te wa ka whakamahia e te Flux cored wire arc fehokotaki'anga hau parakore waro hauhā, waro hauhā me te argon hau hei hau parepare.Me whiriwhiri te momo hau i runga i te waea rere-kore i whakamahia.

He ngawari te katote a Argon, no reira he ngawari ki te whakatutuki i te whakawhitinga pananga i roto i te pewa argon.A, no te te ihirangi argon o ranunga hau e kore e iti iho i te 75%, ka taea e te rere fehokotaki'anga waea pewa fehokotaki'anga ki te whakatutuki i te whakawhiti jet pūmau.Na te hekenga o te ihirangi argon, ka piki te hohonutanga o te kuhu, engari ka heke te pumau o te pewa ka piki te reiti mokowhiti.No reira, ko te ranunga hau tino pai ko te 75%Ar+25%CO2.I tua atu, ka taea hoki te whakamahi Ar+2%O2 mo te ranunga hau.

Ina whiriwhiria te hau CO2 parakore, ka pirau i raro i te mahi a te wera arc ka whakaputa i te maha o nga ngota hāora, ka oxidize te konupora, te silicon me etahi atu mea i roto i te puna rewa, ka arahi ki te wera o nga huānga whakakotahi.Na reira, me whakamahi te waea whakapiri me te konupora teitei me te ihirangi silicon.

Wā tuku: Mei-09-2023